Mineral Based Industries

Manufacturing Industries of Class 10

IRON AND STEEL INDUSTRY:

History and present status:

- First industry was established at Portonova in Tamil Nadu, followed by Kulti in West Bengal.

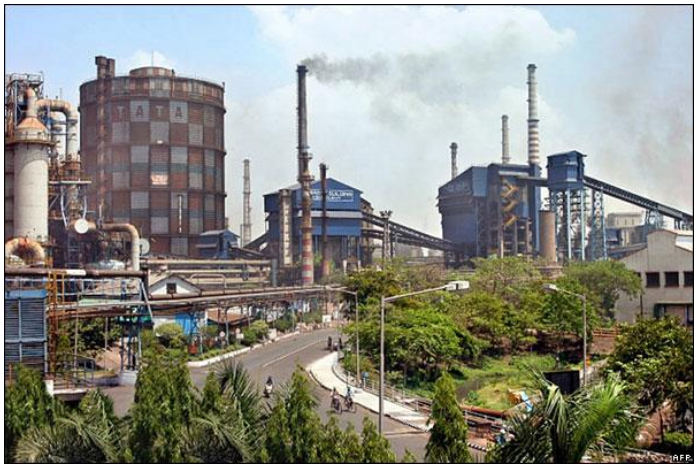

- First integrated steel plant came up at Jamshedpur in 1907.

- Presently there are 10 primary integrated Iron and Steel plant and around 200 mini steel plants.

Importance:

The iron and steel Industry is the basic industry since all the other industries — heavy, medium and light, depend on it for their machinery. Steel is needed to manufacture a variety of engineering goods, construction material, defence, medical, telephonic, scientific equipment and a variety of consumer goods.

Steel plant in Jamshedpur

Production and consumption of steel is often regarded as the index of a country’s development. Iron and steel is a heavy industry because all the raw materials as well as finished goods are heavy and bulky entailing heavy transportation costs. Iron ore, coking coal and lime stone are required in the ratio of approximately 4 : 2 : 1. Some quantities of manganese, are also required to harden the steel.

Today with 32.8 million tons of steel production, India ranks ninth among the world crude steel producers. It is the largest producer of sponge iron. Inspite of large quantity of production of steel, per capita consumption per annum is only 32 kg.

In the 1950s China and India produced almost the same quantity of steel. Today, China is the largest producer. China is also the world’s largest consumer of steel. In 2004, India was the largest exporter of steel which accounted for 2.25 per cent of the global steel trade.

Reason for concentration of Iron and Steel Industry in Chotanagpur plateau:

- This industry in concentrated into Chotanagpur plateau because of the relative advantages this region has for the development of this industry.

- Chotanagpur plateau has rich reserves of Iron ore, coal and lime stone and they are found very close to each other. This reduces transportation cost.

- Damodar River and its tributaries provide water needed by this industry.

- This region has developed thermal and hydro power plants which provide electricity.

- Cheap and skilled labour is available.

- This region has developed network of railways and roadway.

- Kolkata and Haldia ports are very close to this region which facilitates export.

Problems of Iron and steel industry:

- High costs and limited availability of coking coal

- Lower productivity of labour

- Irregular supply of energy and

- Poor infrastructure.

ALUMINIUM:

In 2004, India produced over 600 million tons of aluminium. Bauxite, the raw material used in the smelters is a very bulky, dark reddish coloured rock. The flow chart given below shows the process of manufacturing aluminium. Regular supply of electricity and an assured source of raw material at minimum cost are the two prime factors for location of the industry.

Aluminium Smelting:

Aluminium smelting is the second most important metallurgical industry in India. It is light, resistant to corrosion, a good conductor of heat, mallable and becomes strong when it is mixed with other metals. It is used to manufacture aircraft, utensils and wires. It has gained popularity as a substitute of steel, copper, zinc and lead in a number of industries. There are 8 aluminium smelting plants in the country located in Orissa (Nalco and Balco), West Bengal, Kerala, Uttar Pradesh, Chattisgarh.

Ratio between Ores and Aluminium

4 to 6 tons of bauxite →2 tons of alumina → 1 ton of alumnium

CHEMICAL INDUSTRY:

The Chemical industry in India is fast growing and diversifying. It contributes approximately 3 per cent of the GDP. It is the third largest in Asia and occupies the twelfth place in the world in term of its size. It comprises both large and small scale manufacturing units. Rapid growth has been recorded in both inorganic and organic sectors. Inorganic chemicals include sulphuric acid (used to manufacture fertilisers, synthetic fibres, plastics, adhesives, paints, dyes stuffs), nitric acid, alkalies, soda ash (used to make glass, soaps and detergents, paper) and caustic soda. These industries are widely spread over the country.

petro-chemical industries for Organic chemicals include petrochemicals, which are used for manufacturing of synthetic fibers, synthetic rubber, plastics, dye-stuffs, drugs and pharmaceuticals. Organic chemical plants are located near oil refineries or petrochemical plants. The chemical industry is its own largest consumer. Basic chemicals undergo processing to further produce other chemicals that are used for industrial application, agriculture or directly for consumer markets.

Petro-chemical industries

FERTILIZER INDUSTRY:

- First fertilizer industry plant was established at Ranipet in Tamil Nadu in 1906, real growth became with the establishment of plan". at Sindri by the Fertilizer Corporation of India.

- India is the third largest producer of nitrogenous fertiliser. There are 57 fertilizer units manufacturing nitrogenous and complex nitrogenous fertiliser, 29 for urea and 9 for producing ammonium sulphate as a by-product and 68 other small units produce single super phosphate.

Factors that have helped in the widespread location of fertilizer industry in India:

After the Green Revolution the industry expanded to several other parts of the country. Gujarat, Tamil Nadu, Uttar Pradesh, Punjab and Kerala contribute towards half the fertilizer production. Other significant producers are Andhra Pradesh, Orissa, Rajasthan, Bihar, Maharashtra, Assam, West Bengal, Goa, Delhi, Madhya Pradesh and Karnataka.

CEMENT INDUSTRY:

- Cement is raw material as well as a resource in cementing other industry. So it is called infrastructure core industry. Commercial activities in recent time have boosted this industry a lot.

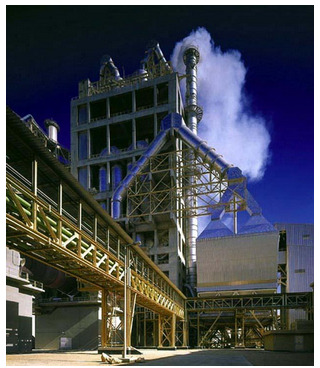

- Construction of roads, dams, airports, bridges, factories, housing colonies, Multistory buildings and now the Malls has completely transformed this industry.

- This industry requires bulky and heavy raw materials like limestone, silica, alumina and gypsum.

- Coal and electric power are needed apart form rail transportation.

yanbu cement factory

So these industries should be located near the source of raw material.

- The industry has strategically located in Gujarat that has suitable access to the market in the Gulf countries.

- The first cement plant was set up in Chennai in 1904. After Independence the industry expanded.

- Decontrol of price and distribution since 1989 and other policy reforms led the cement industry to make rapid strides in capacity, process, technology and production.

AUTOMOBILE INDUSTRY:

Automobiles provide vehicle for quick transport of good services and passengers. Trucks, buses, cars, motor cycles, scooters, three-wheelers and multi-utility vehicles are manufactured in India at various centres. After the liberalisation, the coming in of new and contemporary models stimulated the demand for vehicles in the market, which led to the healthy growth of the industry including passenger cars, two and threewheelers. This industry had experienced a quantum jump in less than 15 years. Foreign Direct Investment brought in new technology and aligned the industry with global developments. At present, there are 15 manufacturers of passenger cars and multiutility vehicles, 9 of commercial vehicles, 14 of the two and three-wheelers. The industry is located around Delhi, Gurgaon, Mumbai, Pune, Chennai, Kolkata, Lucknow, Indore, Hyderabad, Jamshedpur and Bangalore.

India's automobile industry

INFORMATION TECHNOLOGY AND ELECTRONICS INDUSTRY:

- The electronics industry covers a wide range of products from transistor sets to television, telephones, cellular telecom, pagers telephone exchange, radars, computers and many other equipments required by the telecommunication industry.

Silicon Valley

- Bangalore has emerged as the electronic capital of India. Other important centres for electronic goods are Mumbai, Delhi, Hyderabad, Pune, Chennai, Kolkata, Lucknow and Coimbatore.

- Software technology parks provide single window service and high data communication facility to software experts.

- A major impact of this industry has been on employment generation. Upto 31 March 2005, the IT industry employed over one million persons.

- This number is expected to increase eight-fold in the next 3 to 4 years. It is encouraging to know that 30 per cent of the people employed in this sector are women.

- This industry has been a major foreign exchange earner in the last two or three years because of its fast growing Business Processes Outsourcing (BPO) sector.

- The continuing growth in the hardware and software is the key to the success of IT industry in India.

Gas turbine rotor on assembly bed at BHEL, Hyderabad

Related Topics