Rolling Resistance

Rolling resistance is the force required to overcome the resistance encountered when a body rolls on a surface. The motion and energy consumption of a vehicle are greatly influenced by the rolling resistance it encounters. Rolling resistance plays a significant role in determining the overall efficiency and energy consumption of the vehicle. It is a crucial consideration in various engineering applications involving rolling objects, such as vehicle design, tire performance, and the design of rolling bearings.

Rolling resistance, also known as rolling friction, is the resistance encountered by a rolling wheel as it deforms the surface at the point of contact. When a wheel rolls, the interaction between the contacting surfaces leads to deformation, which generates a resistive force known as rolling resistance. It is important to note that rolling resistance differs significantly from sliding friction in its characteristics and effects. Unlike sliding friction, rolling resistance is not tangential and represents a distinct form of resistance.

Analysis of Rolling Resistance

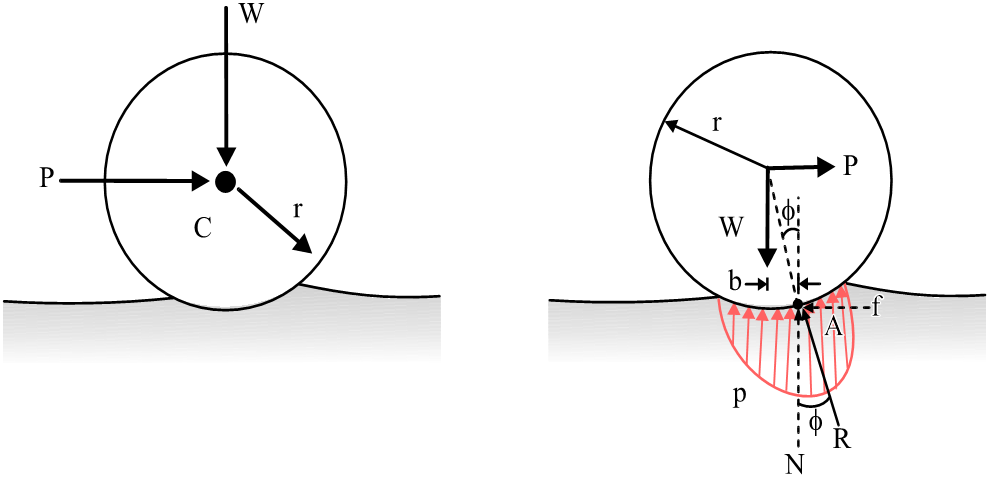

To understand rolling resistance, let's consider a wheel under the action of a horizontal force P applied at its center to produce rolling. Assuming no slippage, the deformed surface (shown exaggerated) exerts pressure on the wheel, resulting in a resultant contact force R at point A.

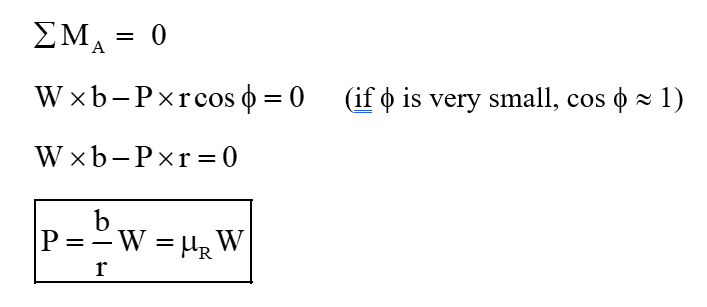

Equilibrium requires the resultant contact force to pass through the wheel's center C. To find the necessary force P for constant rolling speed, we'll analyze moments about A.

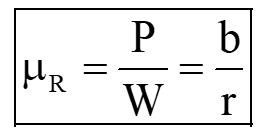

- Here, μ R is the coefficient of rolling resistance, and it is the ratio of the resisting force (P) required to maintain a constant rolling speed to the weight (W) of the rolling object.

By observing above relation, we can deduce that the coefficient of rolling resistance (μ R ) can be minimized by increasing the wheel radius (r) and decreasing the distance b. Reducing surface deformation is vital, which is why train wheels and rails are constructed with hard steel to minimize deformations and thereby decrease rolling resistance.

- The distance b in the above equation depends on various parameters, including the elastic and plastic properties of the materials, wheel radius, travel speed, and surface roughness.