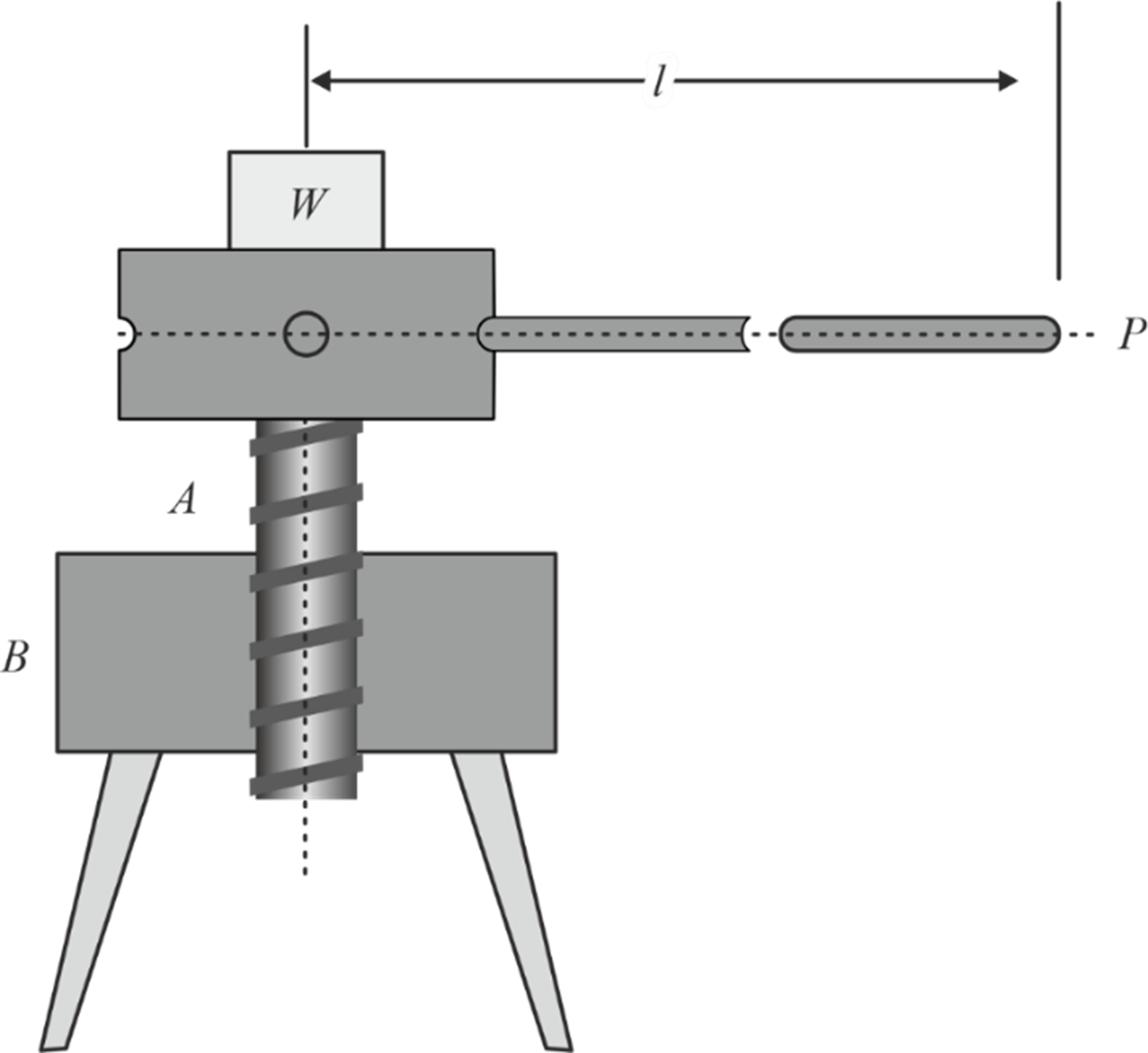

Screw Jack: A screw jack or simply a jack is a mechanical device used to lift heavy loads vertically or apply large forces by converting rotational motion into linear motion. It is designed to effortlessly lift heavy loads by applying relatively smaller forces. Screw jacks are commonly used in various industries, including construction, manufacturing, and automotive, to lift heavy objects, support structures, and apply controlled forces.

Components of Screw Jack

Screw jacks consist of three primary components:- Screw: The screw is a threaded rod that forms the main element of the jack. It has a helical thread along its length, allowing it to move linearly when rotated. When it comes to power or motion transmission, the square thread demonstrates greater efficiency compared to the V-thread. Therefore, the focus of the analysis will be solely on the square thread.

- Nut: A nut is a specially designed component that engages with the screw's thread. The nut serves as a stable support frame with a broad base that remains stationary, providing a solid foundation on the ground.

- Handle or Lever: The handle or lever provides a means to rotate the screw, enabling manual operation of the screw jack. It allows the user to apply force and control the lifting or lowering process.

Square Threaded Screw

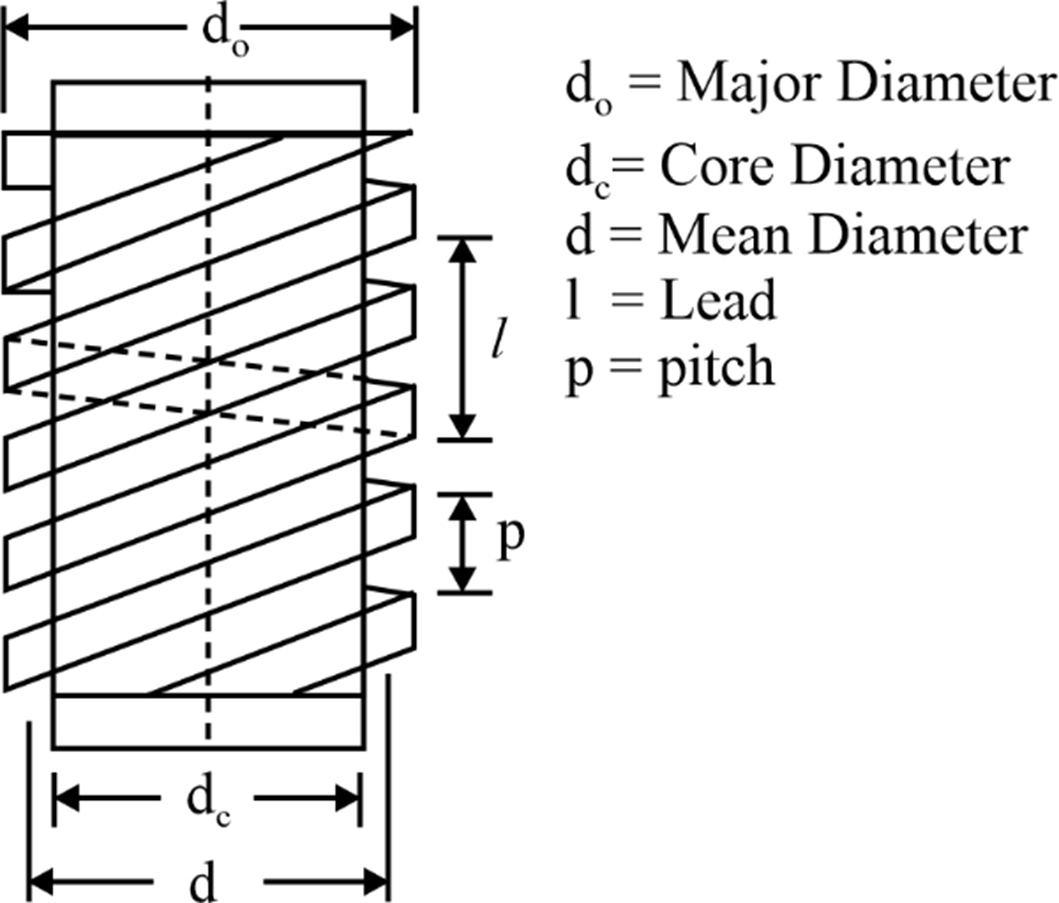

Some essential terminology related to the square threaded screw is being discussed here.

- Pitch: The pitch is the distance between corresponding points on adjacent threads, measured parallel to the axis of the screw.

-

Lead:

The lead is the axial distance traveled by a screw thread in one complete revolution.

- When the lead of a screw is equal to its pitch, it is known as a single-threaded screw.

- A multi-threaded screw has more than one thread cut within one lead distance.

Mathematically, Lead = Pitch × Number of threads.

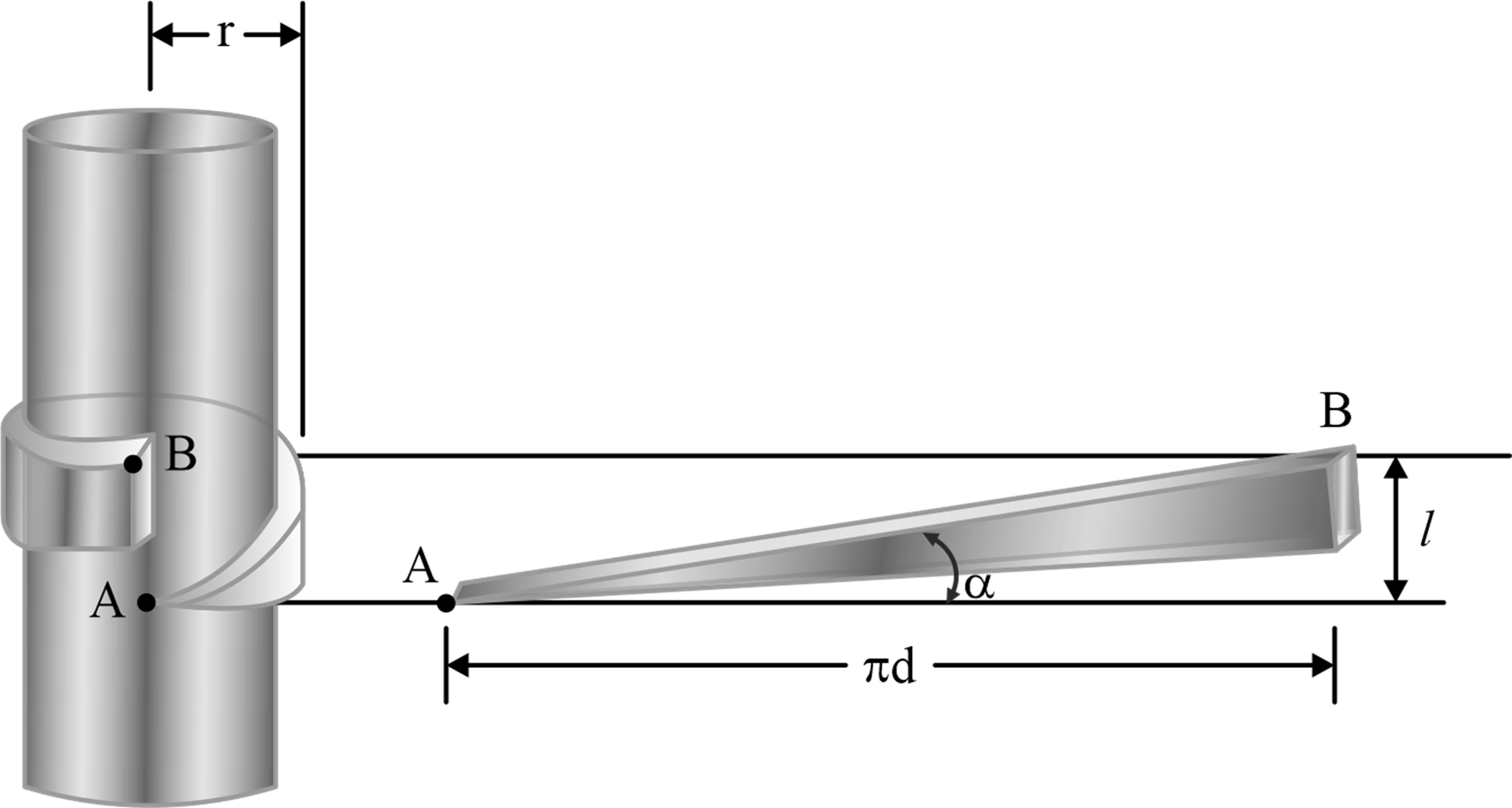

- Slope of the thread: It is the inclination of the thread with horizontal.

Where,

α = Angle of inclination of the thread,

p = Pitch of the screw,

d = Mean diameter of the screw, and

n = No. of threads in one lead.

Effort Required to Raise the Weight

The working principle of the screw jack is based on the inclined plane.

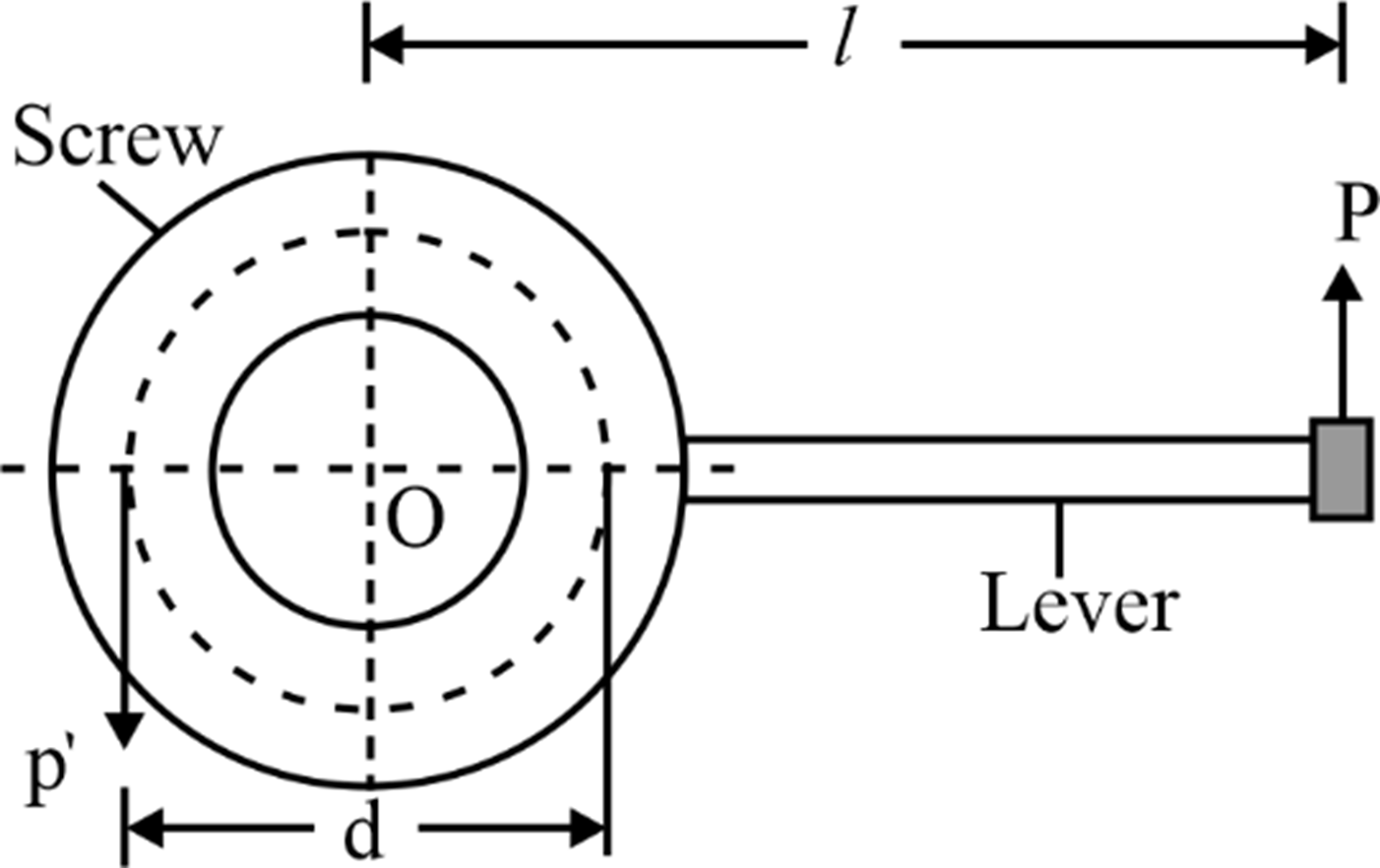

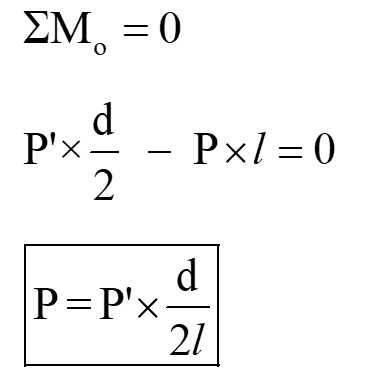

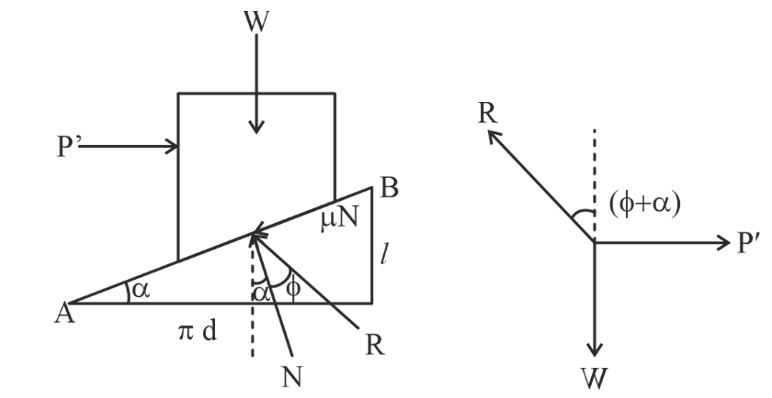

The top view of the screw and lever arrangement is shown in the figure below. The force applied at the end of the lever is denoted as P, which is transmitted as an equivalent effort at the mean radius of the screw, (d/2. where d is the mean diameter of the screw). By calculating moments of the forces about the center of the screw, the following expressions are obtained:

The above expression is used to calculate the effort applied at the end of the lever when a known value of P’ is given.

The above expression is used to calculate the effort applied at the end of the lever when a known value of P’ is given.

The screw jack raises the load by generating friction force F and normal reaction N at the contact surfaces of the threads. The combined force R, resulting from these two forces, is depicted in the figure below. This force R acts at an angle Φ (angle of friction) with the normal reaction.

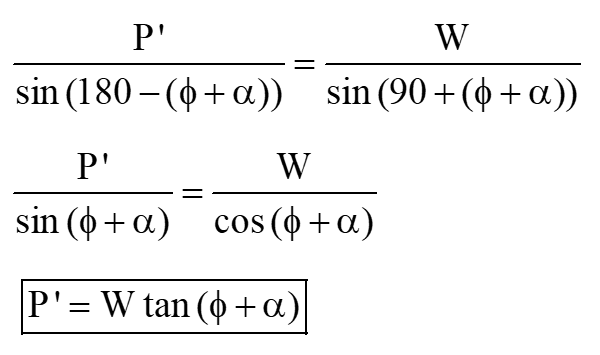

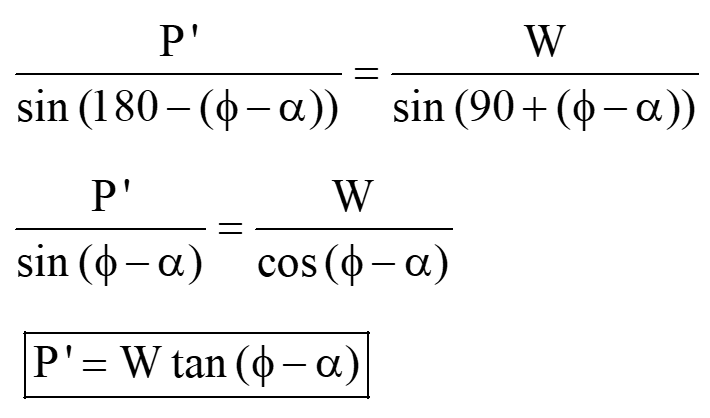

From above force diagram, by using Lami's theorem;

From above force diagram, by using Lami's theorem;

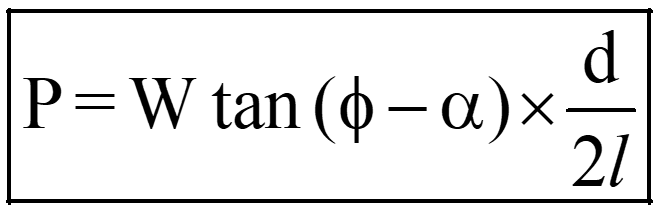

Effort required at end of lever to raise the load,

Effort required at end of lever to raise the load,

Moment required to raise the load,

Moment required to raise the load,

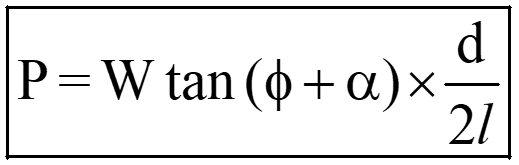

Effort Required to Lower the Weight

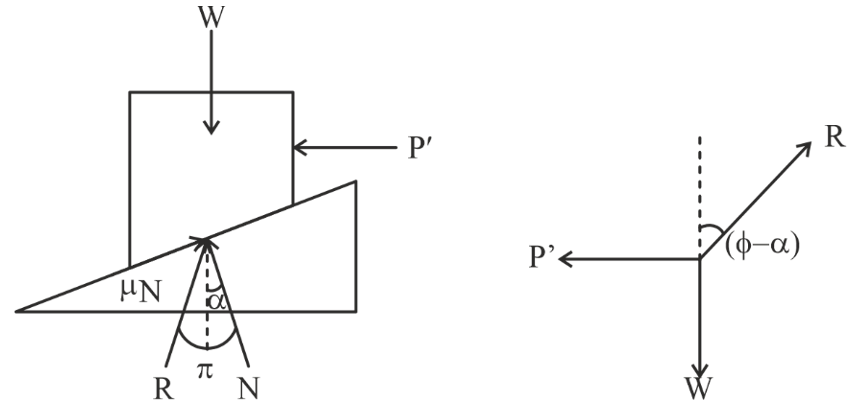

When the load is being lowered, the direction of the friction force will be reversed, causing the resultant reaction force R to shift accordingly, as illustrated in the following diagram: From above force diagram, by using Lami's theorem;

From above force diagram, by using Lami's theorem;

Note: When the effort required becomes negative or zero, this signifies that the system becomes reversible, allowing the load to be lowered with no external effort.

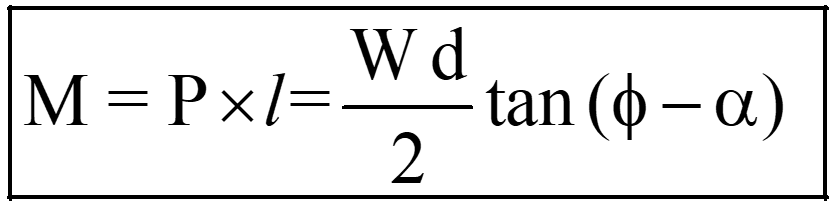

Effort required at end of lever to lower the load; Moment required to lower the load;

Moment required to lower the load;

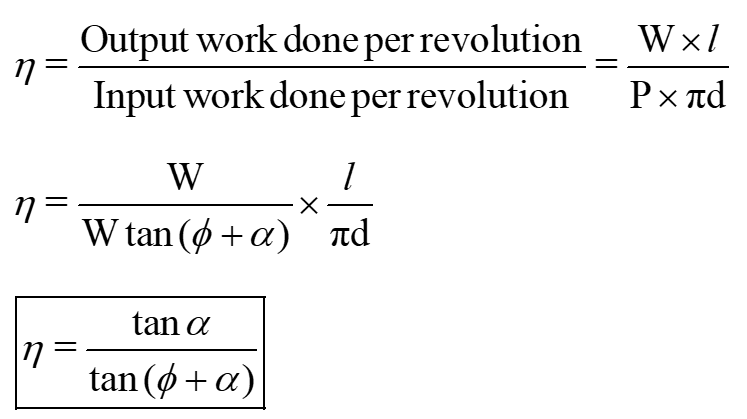

Efficiency of Screw Jack

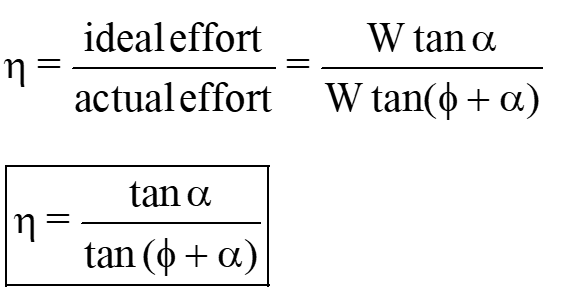

Efficiency of the screw jack is defined as the ratio of the output work done per revolution to the input work done per revolution.

Or

If there were no friction between the screw and the nut, the angle Φ would be zero. In such a scenario, the effort required (P o ) to lift the same load would be determined by the equation: P o =W tanα The efficiency of a screw jack is given by, The above relation shows that the screw jack's efficiency is independent of the weight lifted or the amount of effort applied.

The above relation shows that the screw jack's efficiency is independent of the weight lifted or the amount of effort applied.

Note:

-

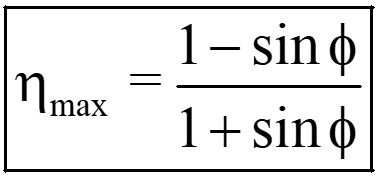

To determine the maximum efficiency condition, we differentiate η with respect to α and equate the derivative to zero. The maximum efficiency of screw jack is given as

- A non-reversible or self-locking machine is one that cannot perform work in the reversed direction after the effort is removed. This occurs when their efficiency is limited to 50% or lower.