CBSE Class 8 Geography Notes Chapter 5: Chapter 5 of CBSE Class 8 Geography, "Industries," introduces the different types of industries: primary (extraction of raw materials), secondary (manufacturing of goods), and tertiary (services). It explains the factors influencing the location of industries, such as raw materials, labor, water, energy, transport, and market access.

CBSE Class 8 Geography Notes Chapter 5 also discusses the global distribution of industries and the significance of industrial regions. Additionally, it emphasizes the environmental impact of industrial activities and the need for sustainable practices to ensure balanced industrial development and environmental conservation.CBSE Class 8 Geography Notes Chapter 5 Overview

CBSE Class 8 Geography Notes Chapter 5 PDF

The chapter touches on the environmental impact of industries, stressing the importance of sustainable practices and the need to balance industrial growth with environmental conservation. Hence, we have provided CBSE Class 8 Geography Notes Chapter 5 Industries pdf-CBSE Class 8 Geography Notes Chapter 5 PDF

CBSE Class 8 Geography Notes Chapter 5 Industries

Here we have provided CBSE Class 8 Geography Notes Chapter 5 Industries -Classification of Industries

Industries are classified on the basis of raw materials, size and ownership. Industries are divided into four categories based on the raw materials they use: forest, marine, mineral, and agricultural. The food processing, vegetable oil, cotton textile, dairy, and leather industries are a few examples of agro-based industries that employ plant and animal-based products as their basic materials. Mineral-based industries: Iron, which is produced from iron ore, is one product of these industries. Iron is used as a raw material to make many other products, including heavy machinery, building materials, and railway coaches. Primary industries in this sector rely on mineral ores as their raw materials. Seafood processing and fish oil manufacture are two examples of marine-based industries that use items from the sea and oceans as raw materials. Industries reliant on forests: pulp and paper, medicines, furniture, and construction are examples of industries that use forest products as raw materials. Industries Divided Into Groups Based on Size: Size is defined as the amount of money invested, the workforce size, and the production volume—which is divided into small- and large-scale industries.-Home industries, also known as cottage industries, in which goods are made by artisans by hand; examples of this type of industry include basket weaving, ceramics, and other handicrafts. Small-scale industries: They employ less money and technology. The production of autos and heavy machinery is a big-scale industry, but the silk weaving and food processing sectors are small-scale. big-scale industries generate vast volumes of goods, need larger capital investments, and use superior technology. Ownership is the basis for classifying industries into four categories: joint, cooperative, state-owned, and private. Industries in the private sector that are owned and run by a single person or group of people. Public sector industries include Steel Authority of India Limited and Hindustan Aeronautics Limited, which are owned and run by the government. Joint sector industries, such as Mauti Udyog Limited, are owned and run by the government as well as a single person or group of people. Cooperative Sector Industries: Anand Milk Union Limited and Sudha Dairy are owned and run by producers or suppliers of labour, raw materials, or both.Factors Affecting the Location of Industries

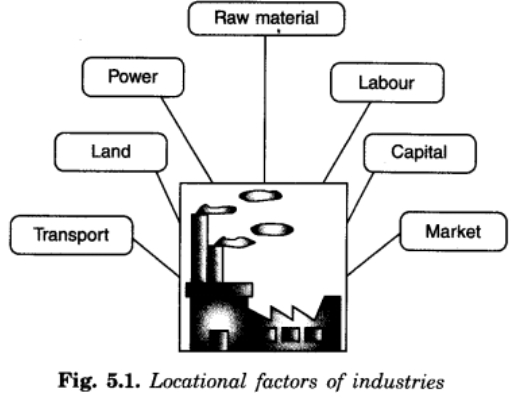

Accessibility of raw materials, land, water, labour, power, capital, transportation, and markets: Industries are typically located in areas with easy access to these resources; the government offers incentives such as subsidised electricity, reduced transportation costs, and other infrastructure to enable the location of industries in underdeveloped areas; and industrialisation frequently contributes to the development and expansion of towns and cities.Industrial System

The Industrial System consists of inputs, processes and outputs:

Raw materials, labour, and the price of land, transportation, electricity, and other infrastructure are considered inputs. processes are a broad category of operations that transform raw materials into final goods. The final product and the money made from it are the outputs.Industrial Regions

The major industrial regions of the world are found in temperate regions, close to seaports, and particularly close to coalfields. Industrial regions arise when several industries locate near to one another and share the benefits of their proximity. These regions include eastern North America, western and central Europe, eastern Europe, and eastern Asia. India's Industrial Areas: Mumbai the Kollam-Thiruvananthapuram industrial cluster; the Pune cluster; the Bangalore-Tamil Nadu region; the Hugli region; the Ahmedabad-Baroda region; the Chottanagpur industrial belt; the Vishakhapatnam-Guntur belt; and the Gurgaon-Delhi-Meerut region.Distribution of Major Industries

The three largest industries in the world are information technology, textiles, and iron and steel. The iron and steel industries are situated in Germany, the United States of America, China, Japan, and Russia. The countries with the largest textile industries are Taiwan, South Korea, Hong Kong, Japan, and India. The Bangalore area of India and Silicon Valley in Central California are important centres of the information technology sector.Iron and Steel Industry

This industry serves as a feeder, producing goods that are used as raw materials for other industries. Its inputs include raw materials like iron ore, coal, and limestone as well as labour, capital, a location, and other infrastructure. Iron ore is converted into steel through a number of steps, including smelting and refinement in a blast furnace. The finished product is steel, which can be used as raw material by other industries.Steel

robust, easily formed, cut, or formed into wire. Small amounts of other metals, such as copper, nickel, and aluminium, can be added to steel to create special alloys.Important steel-producing centres

West Bengal, Jharkhand, Odisha, and Chhattisgarh are the four states that make up the region that includes Bhilai, Durgapur, Burnpur, Jamshedpur, Rourkela, and Bokaro. Salem in Tamil Nadu; Visakhapatnam in Andhra Pradesh; Bhadravati and Vijay Nagar in Karnataka.Jamshedpur

Prior to 1947, the nation's sole privately held iron and steel plant was Tata Iron and Steel Company Limited (TISCO). However, upon independence, the government took the lead and established other iron and steel mills. TISCO was founded in Sakchi, Jharkhand, in 1907, close to the meeting point of the Subarnarekha and Kharkai rivers. Later on, Sakchi became Jamshedpur.Benefits of the place

Kalimati station on the Bengal-Nagpur railway line is only 32 kilometres distant. In close proximity to supplies of coal, manganese, and iron ore; also, Kolkata offered a sizable market. Jharia coalfields supply TISCO with coal, while Odisha and Chhattisgarh supply iron ore, limestone, dolomite, and manganese. The rivers Kharkai and Subarnarekha guaranteed an adequate supply of water. Governmental efforts supplied sufficient funding for its subsequent development.Pittsburgh

An important American steel city benefits from its geographic location. The Pittsburgh area is home to numerous factories that use steel as their raw material to manufacture heavy machinery, railway equipment, and rails. While raw materials like coal are readily available locally, iron ore is obtained from iron mines in Minnesota, which are located approximately 1500 km away from Pittsburgh. The Great Lakes waterway runs between these mines and Pittsburgh, making it one of the most cost-effective routes for shipping ore in the world. Steel is transported by trains.Cotton Textile Industry

Weaving fabric from yarn is an age-old craft. The basic materials used to make cloth are cotton, wool, silk, jute, and flax. The textile business is segmented based on these raw materials. The raw material, fibres, might be synthetic or natural. Natural fibres: derived from jute, cotton, linen, silk, and wool One of the oldest industries in the world is that of man-made fibres, such as rayon, polyester, acrylic, and nylon. Until the 18th century, cotton cloth was made by hand using wheels and looms, until the industrial revolution. Power looms of the 18th century helped the cotton textile industry grow, first in Britain and then throughout the world. Today, India, China, Japan, and the USA are major producers of cotton textiles. The manufacturing of these items was time-consuming and costly. The traditional cotton textile industry was unable to compete with the new textile mills of the West that produced inexpensive and high-quality fabrics through mechanised industrial units. The first successful mechanised textile mill was established in Mumbai in 1854. Mumbai has a warm, humid climate, a port for importing machinery, and a reputation for producing high-quality gold-wrought cotton. The region's industry grew quickly due to the availability of raw materials and skilled labour. Originally, the states of Maharashtra and Gujarat had a favourable humid climate, but today, humidity can be artificially created. Other significant cities include Coimbatore, Kanpur, Chennai, Ahmedabad, Mumbai, Kolkata, Ludhiana, Puducherry, and Panipat.Ahmedabad

Located in Gujarat on the banks of the Sabarmati River, the mill was first established in 1859. It is the second largest textile city in India, after Mumbai. It is often referred to as the "Manchester of India." Situated close to cotton-growing regions, it offers easy access to raw materials and an ideal climate for spinning and weaving. The mills can easily establish themselves there thanks to the flat terrain and easy availability of land, which also provides both skilled and semi-skilled labour. Problems in Ahmedabad textile mills: A number of textile mills closed as a result of the introduction of new textile hubs in the nation and the failure to upgrade the machinery and technology in the Ahmedabad mills. The neighbouring Mumbai port helps the import of machinery and the export of cotton textiles.Osaka

a significant Japanese textile hub known as the "Manchester of Japan."- The following geographic elements have contributed to Osaka's textile industry's growth: The vast plain surrounding Osaka made land readily available for the expansion of cotton factories. The River Yodo supplies enough water for the mills, and the warm, humid atmosphere is ideal for spinning and weaving. Labour is also readily available. The port's position makes it easier to import raw cotton and export textiles. Osaka's textile sector is entirely dependent on imported raw materials. Cotton is imported from the United States, China, India, and Egypt. Because of its affordable price and high quality, the final product finds a favourable market and is primarily exported. Even though Osaka is a major textile hub in the nation, other sectors including iron and steel, machinery, shipbuilding, automotive, electrical, and cement have recently displaced the cotton textile industry in the city.Benefits of CBSE Class 8 Geography Notes Chapter 5

The benefits of studying Chapter 5, "Industries," in CBSE Class 8 Geography include:Understanding Economic Processes : The chapter provides insights into how industries function and contribute to economic growth, helping students understand the role of different sectors in the economy.

Knowledge of Industrial Classification : It helps students differentiate between primary, secondary, and tertiary industries, which is fundamental for understanding economic structures.

Awareness of Location Factors : The chapter explains the factors that influence the location of industries, offering students a practical understanding of why industries are situated in specific regions.

Global Perspective : Students gain a global perspective on industrial distribution, learning about key industrial regions worldwide and the role of different countries in the global economy.

Environmental Awareness : The chapter emphasizes the environmental impact of industrial activities, promoting awareness of sustainable industrial practices and the importance of balancing economic growth with environmental conservation.

CBSE Class 8 Geography Notes Chapter 5 FAQs

What are the 4 types of industries?

Why do we need industries?

Why are industries important for us?

Which industry is said to support many industries?

How are industries classified?