Polyhalo Olefins

Polymers of Class 12

Polyhalo Olefins

These are polymers derived from halogen substituted olefins. The important polymers of this class are PVC, PTFE, PCTFE, etc.

(i) Polytetrafluoroethylene (Teflon or PTFE)

It is an addition polymer of tetrafluoroethylene

nCF2 = CF2  (−F2C − CF2−)n

(−F2C − CF2−)n

Tetrafluoro ethylene Teflon

Commercial polymerization of tetrafluoroethylene is essentially aqueous polymerization accomplished by using free radical initiators (persulphate of hydrogen peroxide).

Teflon is a linear polymer with a high density and is resistant towards heat, action of chemicals such as acids and bases. It’s electrical insulation property; weather resistance and chemical resistance are excellent.

Uses:

Major applications of PTFE are as seals films, gaskets, laboratory equipments or components thereof, packings in pumps and valves, stopcocks, machine components, kitchenwares (non−stick PTFE coated pans), etc., and in electrical insulation and electronics. Its high volume cost is a constraint for its use for making large objects. Outstanding weather resistant and chemical resistant polymers are also obtained from polymerization and copolymerization of chlorotrifluoroethylene, vinyl fluoride, vinylidine fluoride and hexafluoropropylene.

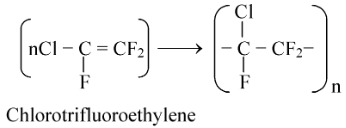

(ii) Polymonochlorotrifluoroethylene (PCTFE)

The properties and uses of PCTEE are similar to that of Teflon.

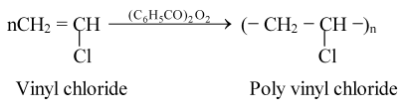

(iii) Polyvinyl chloride (PVC)

It is a monomer of vinyl chloride. It is prepared by heating vinyl chloride in an inert solvent in the presence of peroxides.

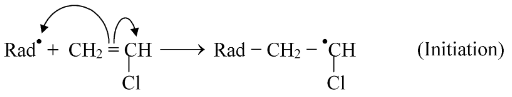

Mechanism: Formation of PVC is a free−radical chain reaction.

(a) Peroxide  Rad∙

Rad∙

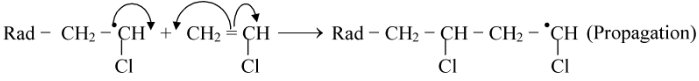

(b)

(c)

Step (c) is repeated till the chain is broken by chain−terminating steps

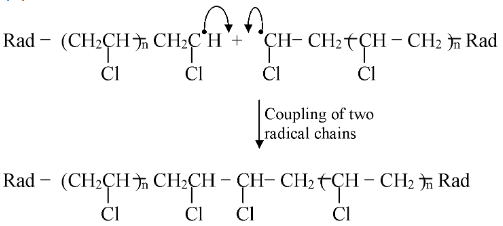

(d)

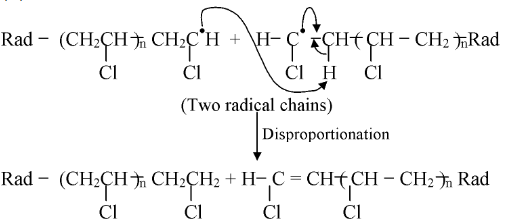

(e)

It is a thermoplastic polymer (hard horny material) and its plasticity can be increased by the addition of a plasticizer such as di n−butylphthalate.

Applications of PVC

Both rigid and flexible applications of PVC have been developed. Rigid applications include chemical plants and equipments, storage tanks, building items, pipes, sheets, specific moulded objects and containers. PVC guttering and waste piping, window frames and transparent roof sheeting are some of its building applications. Floor tiles and wall linings from plasticized PVC are also worthy of mention. Other flexible or semi−rigid applications include packaging items, tubes, pipes and hoses, leather cloths, moulded objects, sheets, films, containers, footwear, belting and wire insulation.

Copolymers of Vinyl Chloride

Copolymers of vinyl chloride (15%) and vinylidene chloride (85%) known as Saran in the trade have excellent chemical resistance including resistance to acids and alkalies and prominent self−extinguishing properties. Saran films (biaxially oriented) have excellent clarity, strength, toughness, water and gas impermeability. The copolymer can be conveniently drawn into a fibre. Saran fibres are suitable as filter cloth for filtering acidic, alkaline or corrosive chemicals.