Extraction Of Lithium

S and P Block Elements of Class 11

Extraction Of Lithium

Minerals of Lithium

(i) Spodumene, LiAl(SiO3)2 – 6% Lithium

(ii) Triphylite (Li, Na)2PO4 (Fe, Mn)3(PO4)2 – 4% Lithium

(iii) Petalite LiAl(Si2O5)4 - 2.7 – 3.7% Lithium

(iv) Lepidolite (Li, Na, K)2(SiO3)3(FOH)2 - 1.5% Lithium

(v) Amblygonite LiAl(PO4)F

It involves the following steps:

1. Preparation of Lithium chloride

The minerals are first of all converted into lithium chloride by any one of the following methods:

(i) Acid treatment method

The finely powdered silicate ore is first heated to about 1373 K to make it more friable and then with  at 523 K. The

at 523 K. The  thus formed is cooled, leached with water and then filtered to remove silica

thus formed is cooled, leached with water and then filtered to remove silica . The filtrate thus obtained is treated with a calculated amount of

. The filtrate thus obtained is treated with a calculated amount of  to precipitate aluminium and iron as carbonates which are filtered off. Excess of

to precipitate aluminium and iron as carbonates which are filtered off. Excess of  is then added to the filtrate to precipitate

is then added to the filtrate to precipitate . This is filtered and dissolved in HCl to obtain LiCl which is purified by extraction with alcohol.

. This is filtered and dissolved in HCl to obtain LiCl which is purified by extraction with alcohol.

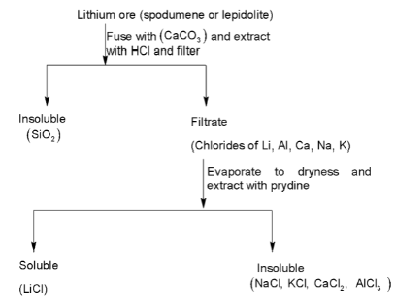

(ii) Fusion method

The powdered silicate mineral is fused with  and the fused mass is extracted with HCl and filtered. The filterate contains chlorides Li, Al, Ca, Na and K whereas silicon is removed as insoluble residue. The filterate is evaporated to dryness and the residue is extracted with pyridine in which only LiCl dissolves. Pyridine is distilled off while LiCl is left behind. The method discussed above may be summed up in the following flow-sheet.

and the fused mass is extracted with HCl and filtered. The filterate contains chlorides Li, Al, Ca, Na and K whereas silicon is removed as insoluble residue. The filterate is evaporated to dryness and the residue is extracted with pyridine in which only LiCl dissolves. Pyridine is distilled off while LiCl is left behind. The method discussed above may be summed up in the following flow-sheet.

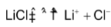

2. Electrolysis of Lithium chloride

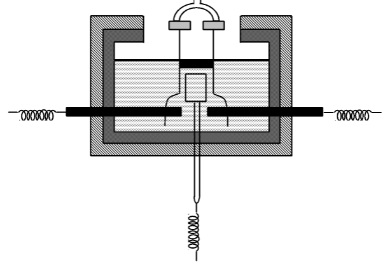

A mixture of dry lithium chloride (55%) and potassium chloride (45%) is fused and electrolysed in an electrolytic cell shown in the figure.

|

|

Potassium chloride is added to increase the conductivity of lithium chloride and to lower the fusion temperature. The cell is operated at a temperature of about 723 K and voltage of 8-9 volts is applied.

As a result of electrolysis, the following reactions take place:

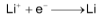

At cathode:

At anode :

Chlorine gas, a valuable by product liberated at the anode leaves the cell through the exit while molten lithium rises to the surface of the fused electrolytes and collects in the cast iron enclosure surrounding the cathode. The metal thus obtained is 99% pure and is preserved by keeping it wrapped in paraffin wax. It may be noted here that lithium being the lightest metal known

(density = 0.534 g  ) can not be stored in kerosene oil since it floats on the surface.

) can not be stored in kerosene oil since it floats on the surface.

Properties of Lithium

(a) Physical Properties

(i) Lithium is a silvery white metal.

(i) It is the hardest alkali metal but still is soft enough to be cut with a knife.

(ii) Atomic and ionic radii of lithium are the lowest amongst alkali metals.

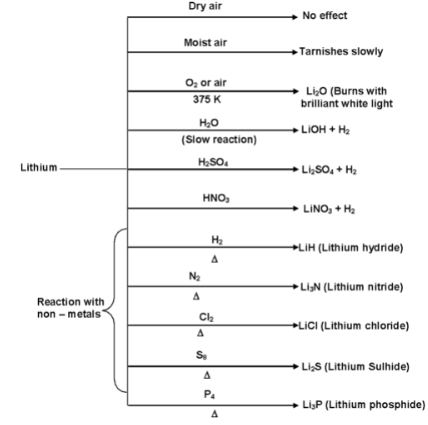

(b) Chemical Properties

Lithium is highly reactive element. However, among alkali metals lithium is the least reactive.

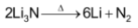

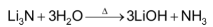

Lithium is the only alkali metal which combines directly with nitrogen to form lithium nitride. Lithium nitride is ionic and is ruby red. On heating it decomposes to its constituent element. It also reacts with water evolving ammonia.

Reaction with ammonia

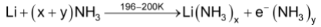

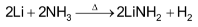

Like other alkali metals, lithium dissolves is liquid ammonia to form a deep blue solution due to formation of ammoniated electrons.

However, when NH3 gas is passed over molten lithium.

Lithium amide is formed

Uses of Lithium

(a) Lithium lead alloy (0.05% Li) which is used for making toughened bearings and sheets for cables.

(b) Lithium – Aluminium alloy has great tensile strength and elasticity like that of mild steel. It is used for air craft construction.

(c) Lithium – magnesium alloy (with 14% Li) is extremely tough and corrosion resistant which is used for armour plate and aerospace components.

(d) Lithium is used for refining of metal like copper and nickel as it combines readily with oxygen and nitrogen and thus removes the last traces of oxygen and nitrogen.

(e) Lithium chloride is used in air conditioning plants to regulate the humidity.

(f) Lithium aluminium hydride (LiAlH4) is used as a reducing agent in synthetic organic chemistry

(g) Lithium carbonate is used in making special variety of glass which is very strong and is weather proof.

- Introduction

- Physical Properties

- Chemical Properties

- General Characteristic Of The Compounds Of The Alkali Metals

- Anomalous Behaviour Of Lithium And Its Diagonal Relationship With Magnesium

- Difficulties Encountered During Extraction Of Alkali Metals

- Sodium

- Compounds Of Alkali Metals

- Alkaline Earth Metals

- Extraction Of Lithium

- Chemical Properties Of Group II elements

- Anamalous Behaviours Of Beryllium

- Manufacture Of Cement

- Silicon

- Exercise 1

- Exercise 2

- Exercise 4

- Exercise 5

- Exercise 6

- Exercise 7

- Exercise 8